The British Occupational Hygiene Society, the leading scientific charity in the protection of health in the workplace is calling for immediate action to prevent further cases of lung disease which is now being reported in the UK for the first time.

What is crystalline silica?

Silica is a common mineral found in the Earth’s crust. It is hard, chemically inert and has a high melting point. It is found in many different materials including quartz, which is the second most common mineral on earth. It is also found in flint, gritstone, sand and sandstone.

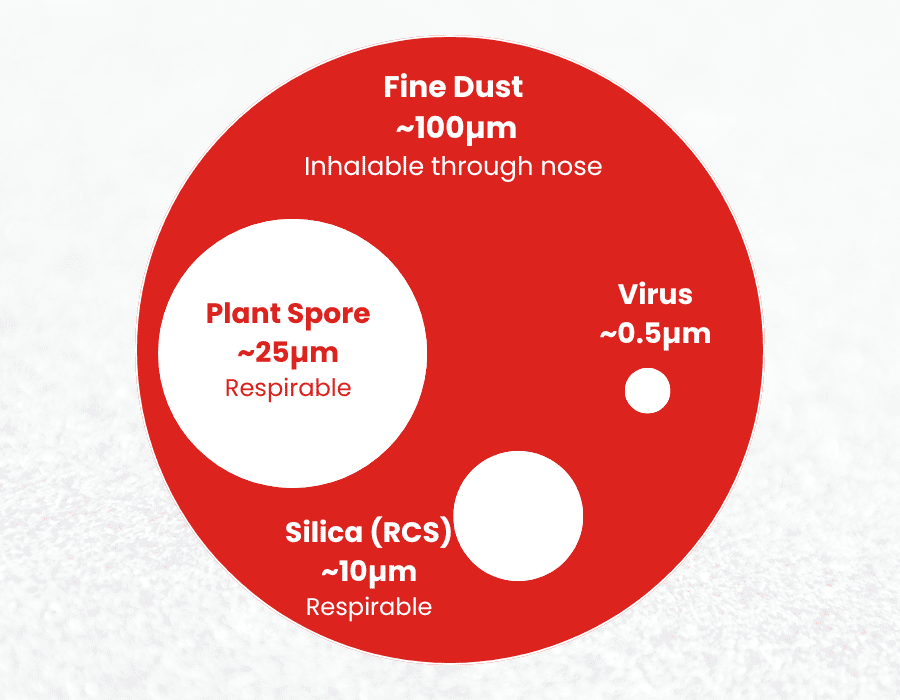

Respirable crystalline silica (RCS)

RCS are very small particles – At least 100 times smaller than ordinary sand you might find on beaches.

The size of a silica (RSE)

Workers who inhale these particles are at increased risk of developing serious silica-related diseases including:

- Silicosis

- Lung cancer

- Chronic obstructive pulmonary disease (COPD)

- Kidney disease

How is RCS generated?

RCS is generated by:

- Drilling and blasting

- Milling, cutting, sawing

- Mixing

- Loading and unloading

- Dry crushing and grinding

- Packing

- Vehicle movements

- Cleaning of processing areas

RCS generated by industry

Aggregates – Sand, gravel, crushed rocks

Calcium silicate – Mixture of sand, lime and water

Cement industry – powder used in binding agent for concrete

Ceramics industry – Usage of silica as structural ingredient

Engineered stones – Vibration and compressing of materials

Expanded clay industry – Ceramic based light-weight aggregate

Foundries – Molds made of bonded silica

Glass industry – Silica sand

What is Silicosis?

Silicosis is an incurable lung disease. This is not a new condition and has been known about for thousands of years, in fact it is oldest known occupational disease, but in recent years it has been more prevalent among workers cutting and finishing engineered stone worktops, which are commonly used for kitchen refurbishments.

Engineered worktops have become popular due to their affordability compared to natural stone. Silicosis is caused when tiny crystalline particles of silica, a mineral found in stone, are inhaled during the cutting, breaking and grinding process.

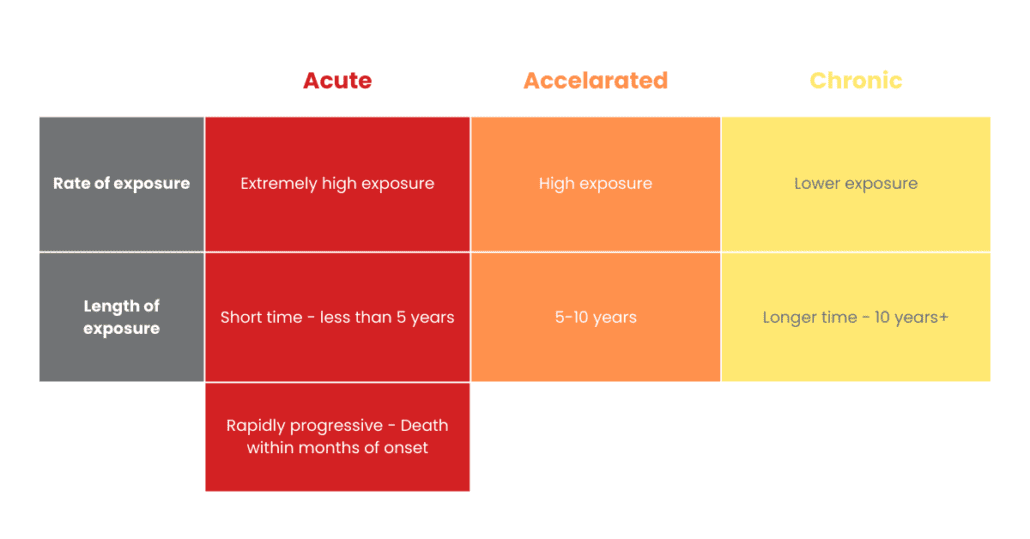

There are three different types of silicosis:

Different types of silicosis – Acute, accelerated and chronic

Acute – This is extremely high exposure over a short period of time (less than 5 years). This would result in rapidly progressive breathlessness and death would usually be within a few months of onset.

Accelerated – This is high exposure over a slightly longer period (between 5-10 years).

Chronic – This is a lower exposure but over a much longer period (10 years+)

A rise in silicosis cases in Australia due to poor regulation and widespread exposure led to a ban of the material entirely which is set to commence on 1 July 2024.

The BOHS President Alex Wilson says “Sadly, there is reasonable probability that there are more cases that have not been detected or reported. Accurate diagnosis of silicosis is difficult, and it can easily be mistaken for a more common complaint, sarcoidosis, for example”.

So what is being done to keep workers safe?

What the HSE are doing

A range of different materials including resin, sintered and natural stone products were cut and polished inside HSE’s dust tunnel facility. A HSE multidisciplinary team worked on the project and used a wide range of techniques to characterise the dust and fumes emitted.

This research has helped us understand the properties of the dust so that risk can be assessed appropriately and the current exposure control measures such as tool exhaust ventilation, respiratory protective equipment and help decide on appropriate training for workers and employers.

What are some ways workers can be protected against silica exposure?

Isolation – Enclose the work so all dust is contained within the enclosure and all employees are outside.

Ventilation – Use a local exhaust or vacuum tool system that removes airborne dust. It’s important to:

- Ensure the exhaust is properly designed for it to be an effective control measure.

- Ensure it is consistently set up according to the manufacturer’s specifications.

- Ensure it is maintained for optimal air exhaust and serviced.

- Ensure appropriate training for workers on the proper use and maintenance of the equipment.

Wet cutting – A wet cutting system can minimise the generation of dust. Mixing water with electricity can be dangerous so make sure:

- It is setup and maintained according to the manufacturer’s instructions. This includes measuring water flow rates.

- Appropriate training for workers on the property use and maintenance of the equipment.

Use of RPE – If you have to wear RPE make sure that:

- You are wearing the right type for the job

- You are face-fit tested for tight fitting RPE. Workers need to be clean shaved for the tight-fit type to work effectively.

- Workers are trained of how to use, check and clean RPE

- The filters on reusable RPE are changed in accordance with recommendations

For more advice and guidance on the control of exposure to silica dust for employees read HSE’s guide here

Latest News

Riskex Limited

BizSpace

Linford Forum

18 Rockingham Drive

Milton Keynes

Buckinghamshire

MK14 6LY

What3words reference:

Contact us

Make an enquiry:

Company No. 05174302

VAT No. 844 5092 22